Tana-Tex, a Print-on-Demand Privacy Curtain

Tana-Tex Inc. is revolutionizing the privacy curtain business with technology that allows for seamless curtains produced from an integral mesh fabric.

Anat Unruh, owner of Tana-Tex had been in the privacy curtain business for a while when she got the inspiration for this new product in an unusual place: the tennis court. Traditional privacy curtains had long been created with a mesh section sewn into a woven curtain, or connected by snaps. Anat wondered, why couldn’t these curtains be created seamlessly, like the open and closed areas in a tennis net?

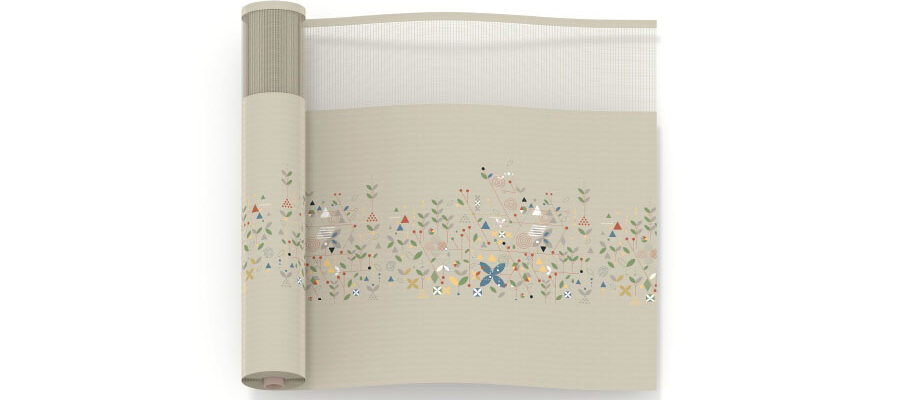

From this idea, the integral mesh product was created. The result is a seamless curtain unlike traditional pieced curtains. This single piece of fabric is constructed all at once, requiring no additional sewing or snaps.

This new mesh fabric creates seamless curtains in a construction with overall greater dimensional stability. And it’s not just the curtain construction that is unique, it is also the fabric construction. Traditional curtains were usually made with two different fibers, polyester for the curtain and nylon for the mesh. However, these two fibers react differently in an environment. Nylon lacks memory and can easily distort with use and look sloppy over time. Tana-Tex curtains are made of a single polyester filament that reacts evenly to any environmental stress. It also launders well, holds its shape over time, and doesn’t pill or absorb moisture.

With this technology as a base, the curtains offer a wide range of design possibilities. Tana-Tex offers solid colors, which are piece-dyed, as well as jacquard woven designs. These curtains are also the ideal product for print on demand technology.

At any given time Tana-Tex has yards of base cloth in inventory, ready for printing when an order is placed. Printed digitally, there are no limitations on color and they use a spectrophotometer to assure a commercial color match.

This printing technology makes it perfect for interior designers looking for a curtain that matches perfectly with a developed design or an existing environment. The results are less institutional and more hospitality, an important trend in healthcare interiors.

In addition to allowing more creative and unique curtains, this technology also has a greatly reduced carbon footprint. The printing process uses 90% less water and 50% less energy than traditional yarn dyeing. It completely eliminates the need for seams and the end product is more durable, which means these curtains last longer and are less frequently replaced. The entire curtain can be laundered at 160º and there are no seams or hems to trap dust or shelter microbes.

Tana-Tex sells its products internationally and domestically through jobbers such as Knoll, Carnegie, Momentum, and DesignTex. Minimum orders are 60 yards, which translates to approximately fifteen curtains.

An idea inspired by a lifelong love of tennis is now a business changing the look of privacy curtains and offering new possibilities for design in health care facilities. If you have a print-on-demand product, consider adding new Design Pool designs to your offerings. Search our library of licensable designs today.

If you are interested in learning more, visit the Tana-Tex website.

Share this post

Author

DESIGN/COLOR TRENDS AND AWESOME INFORMATION IN YOUR INBOX

Sign up for our monthly trend letter