Airstream Reproduction; Recreating a Fabric

Occasionally, at Design Pool, I receive a request to replicate an antique textile, and I rarely say no, if I can. If the company making the request owns the copyright to the design, then this is something I can help them with. If not, I have to politely decline the project. Recreating an antique textile is an intense design challenge that involves research into traditional techniques and manufacturing processes. An example of this type of project is an Airstream reproduction I worked on in 2019.

Airstream was in the process of recreating a 1950s Airstream. They wanted the details to be as close as possible to the original. They contacted me to recreate fabric for the interior cushions. Since they needed a very small amount, digital printing was the most effective way to get the fabric they needed.

A few days after saying yes to the request, a very old, fabric cushion casing arrived in the mail. It was very faded and had seen a lot of wear and spills over the years. My first challenge was to recreate the pattern as closely as possible to the original. The second challenge would be to find a manufacturer whose quality was acceptable and who was willing to print only a few yards.

What is involved in an Airstream reproduction?

Recreating the Graphic

As I got to work on the first challenge, I began by taking apart the original cushion – after asking permission, of course. I used a seam ripper and carefully took each seam apart and ironed each piece flat. Playing with them a bit, I got a sense of what this pattern would look like as a flat piece of fabric.

Next, I photographed each piece and brought them into Photoshop to clean up and crop. From there, I could bring the images into Illustrator and do a 16-color image trace to get the basics of the design into a workable state. While Illustrator does a fairly good job, image trace does tend to shift or meld shapes. Still, this was good enough to use as a beginning template.

With this template, I drew the entire image and figured out its repeat. Since Airstream was only remaking the cushion, I didn’t need to recreate the entire repeat. Instead, I just had to focus on the cushion pieces, showing enough of the design repeat to extend past the sew lines.

This process saved time in the design stage, but also in the manufacturing phase. Rather than print out yardage of the full design and then have the individual cushion shapes cut from that yardage, we created a file to send to the printer that had the cushion shapes nested together on one yard of fabric.

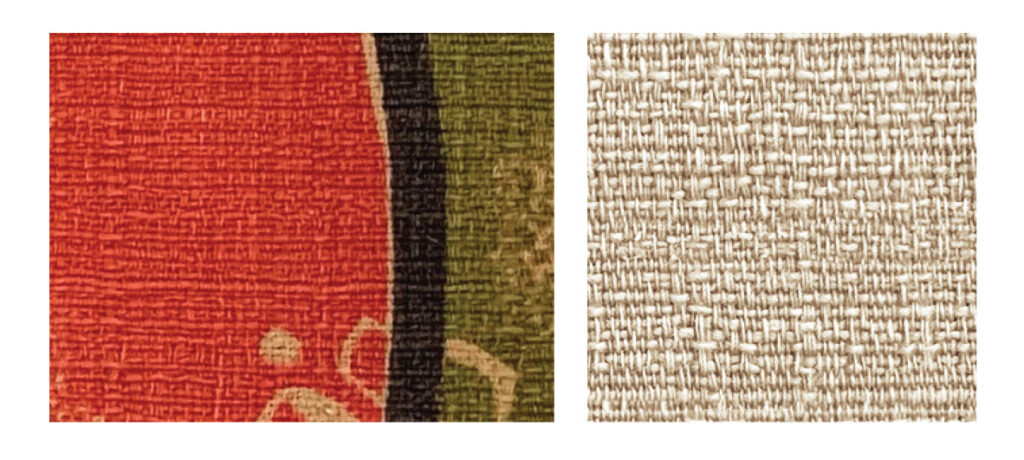

Recreating the Texture

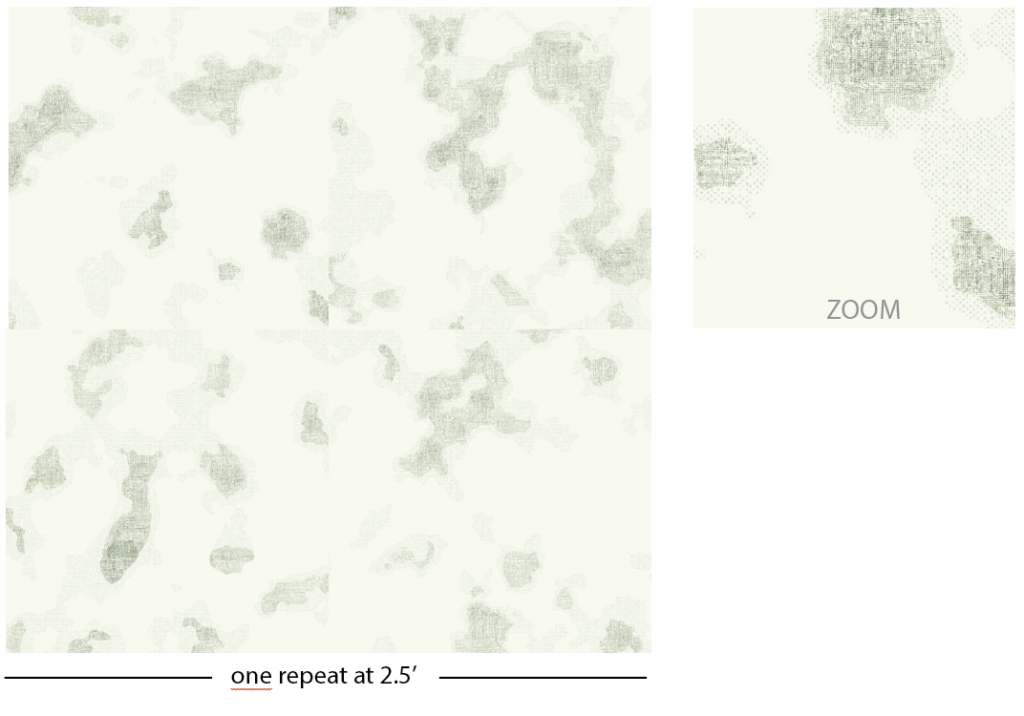

While researching the original cushion, I noted the strong texture of the original basecloth fabric. I knew it would be very challenging, if not impossible, to find a similarly woven fabric to use as a basecloth, especially for only one yard. Still, it was an important element of the original fabric. Rather than print on a texture, I incorporated it into the design as a texture swatch in Illustrator.

For this process, I took a detailed photo of the texture in a solid area. After I brought that photo into Photoshop, I was able to create a swatch that could be put into repeat. This became the texture swatch added to the design in Illustrator.

Recreating the Color

Airstream wanted this fabric to look the way it looked when it was brand new in 1950. However, the fabric from the original cushion had faded a lot over the years. To get a better idea of what the color had been like when it was new, I looked at the seam allowance. On the inside of the seam, where there had been no light, I saw the original color of the fabric.

Working in Photoshop with the texture swatch previously created, I picked colors. Using the color balance slider, I developed a color palette that matched the original colors perfectly.

Time for Printing

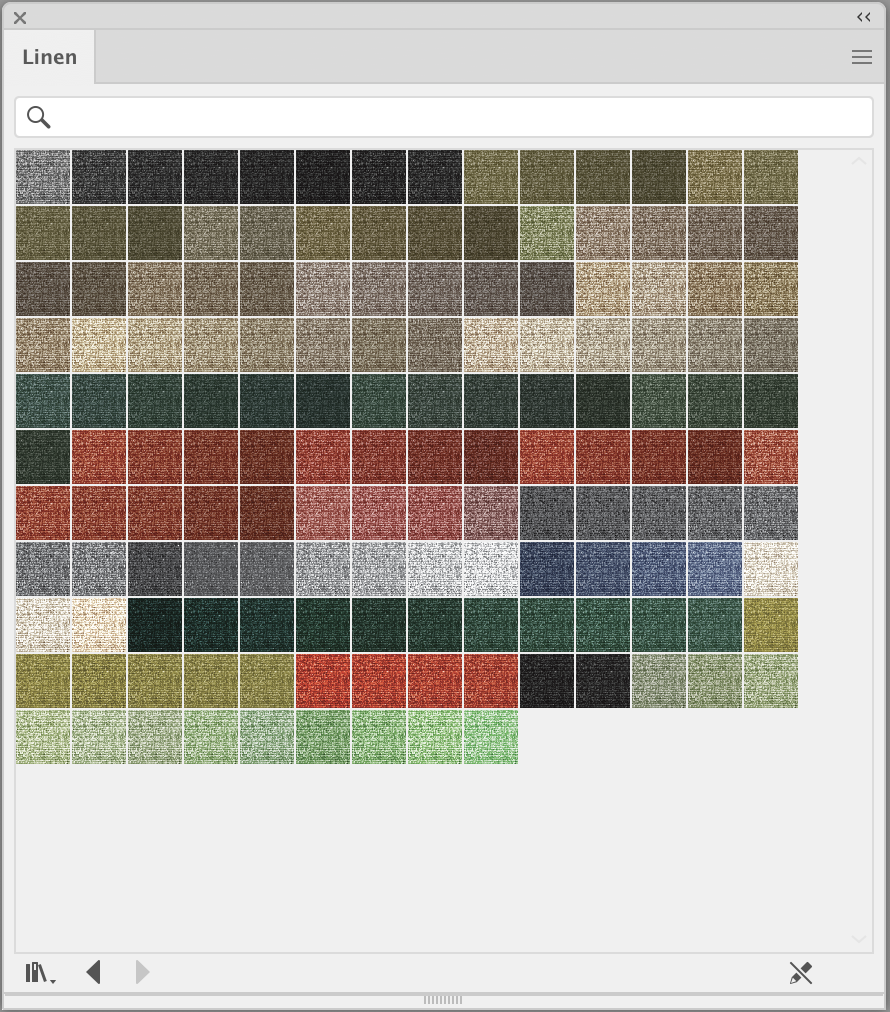

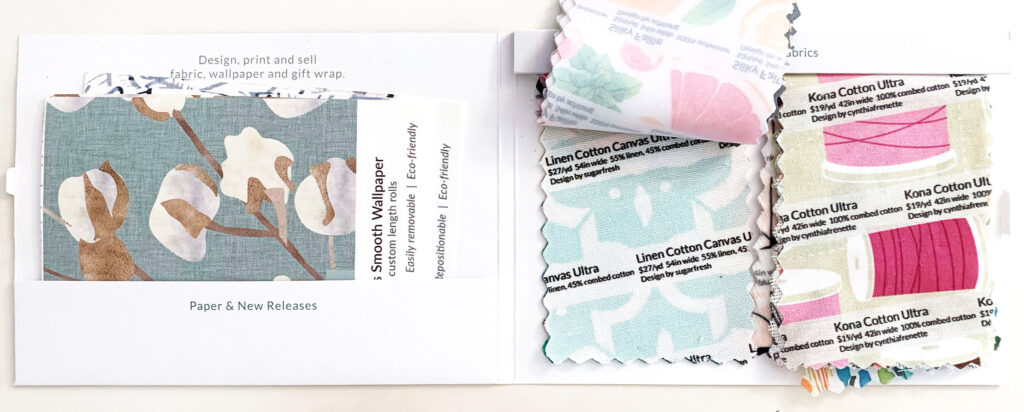

After researching print-on-demand companies, we chose Spoonflower to do the printing. First, I requested their fabric pack so I could evaluate the weight and hand of all the swatches, as well as choose a textured basecloth. I decided to use their Linen Cotton Canvas and ordered as much as needed for manufacturing.

Finishing up with Flooring

With the cushion successfully completed, Airstream asked for the reproduction of the original flooring. This was a bit less involved, as Airstream had a supplier for printing the flooring; they just needed the design. (Had they not, I would have recommended Graphic Image Flooring’s vinyl flooring.) For the floor, we started with a marble pattern and then added a textured swatch to the marble. This created a random texture effect, similar to the original.

As someone who loves Airstreams and fabric of the 50s, this Airstream reproduction project was a blast. Yet, it’s important to mention that any request we receive at Design Pool to replicate a design comes with some initial questions. We always make sure that the person asking us to do the project owns the copyrights to the design and puts that in writing. Simply knocking off a design is not the same as a historical reproduction and is something we would never do here.

Learn more about another historical reproduction project with our partner, Museum L-A.

Share this post

Author

DESIGN/COLOR TRENDS AND AWESOME INFORMATION IN YOUR INBOX

Sign up for our monthly trend letter